Graphite Solutions for Tomorrow's Innovations

Graphite for electrical discharge machining (EDM), as an excellent material with high strength, high temperature resistance, high electrical conductivity, highly corrosion resistance and thermal shock resistance, can perform stable electrical discharge machining and is widely used in manufacturing high precision parts. In addition, graphite has excellent machining properties and can be made into electrode by only taking 1/3–1/10 of the time when compared with metal.

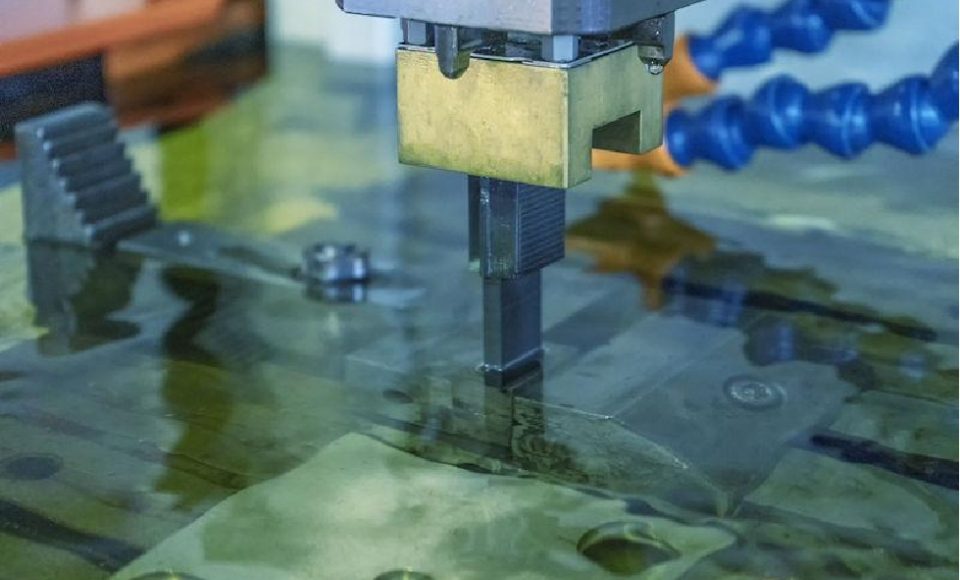

Electrical discharge machining (EDM) is a machining method that removes material by generating high temperature, high pressure, and high-speed physical effects on the workpiece surface through electrical discharge, making it possible to manufacture complex components in a short time and improving manufacturing efficiency.