Graphite Solutions for Tomorrow's Innovations

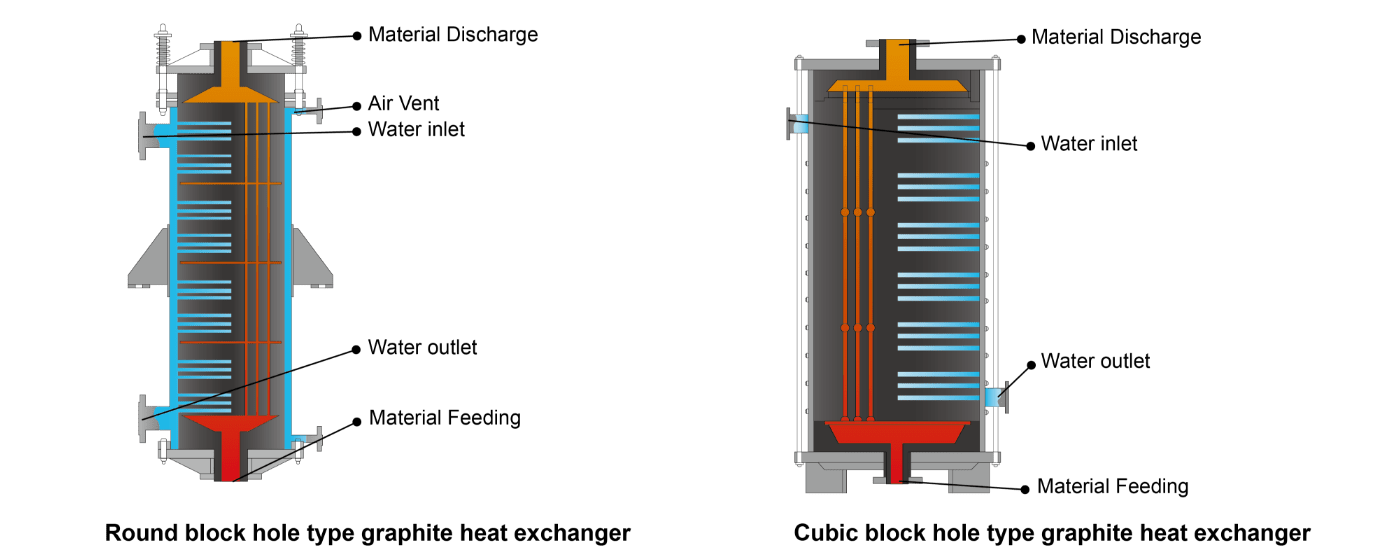

Graphite block heat exchanger are divided round block hole type graphite heat exchangers and cubic block hole type graphite heat exchangers according to their structure. They are composed of several graphite heat exchange blocks with material channels, upper and lower graphite heads, their metal cover plates, a cylindrical steel shell (for round block hole type) or two end side covers (for cubic block hole type), and other main components. The parts are sealed with gaskets and secured with long bolts. They are commonly used in heating, cooling, evaporation and other processes in chemical, petroleum, metallurgy and other industries.

| Material | Material Description | Corrosion Resistance | Limitations | Temperature |

|---|---|---|---|---|

| HMC-1 | Phenolic resin impregnated extruded graphite | Against most common acids | Alkalis, oxidizing chemicals | 200 °C |

| HIS-1 | Phenolic resin impregnated isostatic graphite | Against most common acids | Alkalis, oxidizing chemicals | 220 °C |

| HIS-2 | Carbon impregnated isostatic graphite | Against most common acids + mildly oxidizing media | Strong alkalis, very oxidizing chemicals | 430 °C |

| Silicon Carbide | Sintered silicon carbide | Universal | None | 250 °C |

Notes:

|

||||

Graphite block heat exchanger is an efficient heat transfer equipment that can be divided into round block hole type graphite heat exchanger (left in the picture) and cubic block hole type graphite heat exchanger (right in the picture).

The round block hole type graphite heat exchanger has a series of equally spaced, parallel holes with the same diameter and length that are opened inside the graphite cylinder, and both ends of the holes are connected to the outer surface of the graphite cylinder. Fluid flows in these holes, transfers heat to the graphite block through contact, and then transfers heat to the other side through the conduction of the graphite block.

Cubic block hole type graphite heat exchanger has a series of rectangular cross-section holes that are opened inside the graphite cubic block, and both ends of the holes are connected to the outer surface of the graphite cubic block. Fluid enters from one side of the holes and contacts with neighboring graphite blocks through the holes, thus achieving heat transfer.

In general, their principle is to make use of the channels inside the graphite blocks to conduct heat transfer. Of which, round block hole type graphite heat exchanger features compact structure, small footprint, and high heat transfer coefficient. While cubic block hole type graphite heat exchanger features larger heat exchange area, low fluid resistance, and strong versatility. In practical applications, selecting different types of graphite block heat exchangers according to specific process conditions can effectively improve production efficiency and save energy.