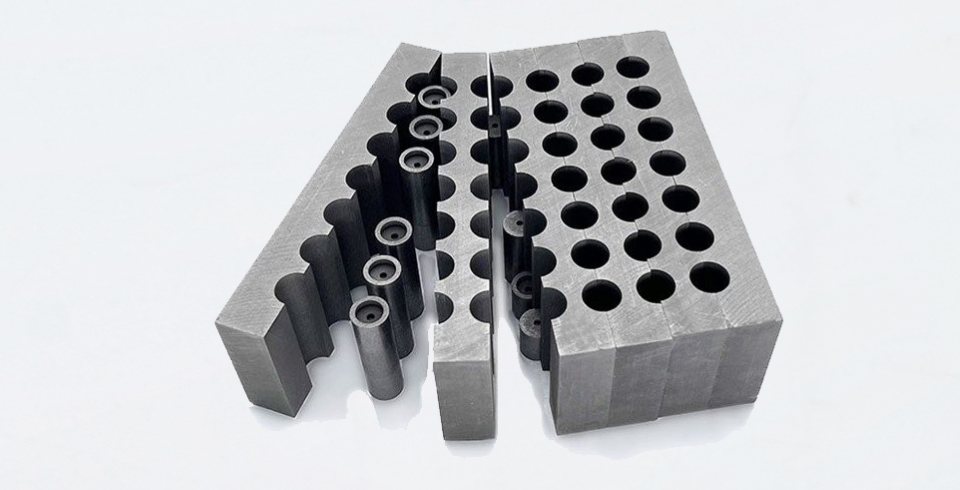

Diamond wire graphite sintering mold

Graphite sintering molds are important tools for manufacturing diamond alloy materials and hard alloy materials. With the rapid development of geological exploration, coal exploration and mining, oil exploration and drilling, and highway cutting, especially the rapid development of granite and marble mining and cutting industry, the demand for diamond alloy materials and hard alloy materials has increased significantly. Therefore, the demand for diamond graphite sintering molds has also increased accordingly.

Graphite itself has good electrical and thermal conductivity, does not react with most molten metals, and does not deform at high temperatures (up to 2700 °C). As the temperature rises, its electrical and thermal conductivity and strength will be enhanced significantly. Besides, its coefficient of thermal expansion is lower than that of metal, making it an ideal material widely used in the powder sintering industry.

| Model | Density (g/cm3) | Particle Size (μm) | Specific Resistance (μΩ.m) | Porosity | Shore Hardness | Compressive Strength (MPa) | Flexural Strength (MPa) | CTE (× 10-6 °C-1) | Application |

|---|---|---|---|---|---|---|---|---|---|

| IS-2 (Isostatic) | 1.76 | 20 | 15 | 20% | 60 | 95 | 50 | 5.9 | Heat exchanger / All kinds of machining |

| IS-3 (Isostatic) | 1.85 | 10 | 12 | 13% | 48 | 85 | 46 | 4.3 | Sintering / All kinds of machining |

| IS-4 (Isostatic) | 1.90 | 5 | 12 | 13% | 48 | 85 | 46 | 4.3 | Sintering / All kinds of machining |

| MD-1 (Molded) | 1.78 | 25 | 12 | 20% | 48 | 80 | 40 | 5 | Sintering / All kinds of machining |

Notes:

|

|||||||||

Among graphite sintering molds, diamond wire graphite sintering molds, diamond core bit graphite sintering molds and diamond blade graphite sintering molds occupy the most part.

Diamond wire graphite sintering mold

Diamond core bit graphite sintering mold

Diamond blade graphite sintering mold

Sintering, also known as frittage, is a general term for the densification process and phenomenon of compacted powder or blanks at high temperatures, i.e., the heat treatment of compacted solid materials. The applied high temperatures and pressures force the atoms in the material to diffuse across particle boundaries, fuse together into a solid block and reduce the porosity, thus enhancing material properties including thermal and electrical conductivity, material strength, integrity, and translucency.

It should be noted that the required heat and pressure for the sintering process must be lower than the melting point of the main material.

Sintering category: According to the composition of the powder material, sintering can be divided into single-phase system (composed of pure metal, compound or solid solution) and multi-phase system (composed of metal-metal, metal-nonmetal, or metal-compound). According to the sintering process, it can be further divided into pressure sintering and pressureless sintering.